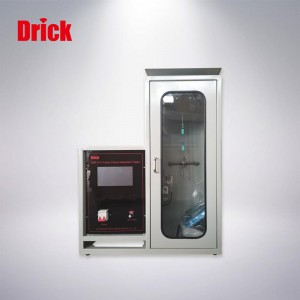

I-DRK-07A Umhloli We-Flame Retardant Wezingubo Zokuzivikela

Izinto zokuhlola: Thola ukuthambekela kwezindwangu ukuqhubeka nokushiswa, ukushunqa kanye ne-carbonization

DRK-07AI-Flame Retardant Testerizingubo zokuzivikela, ezisetshenziselwa ukunquma ukuthambekela kwezindwangu ukushisa, ukushunqa nokushiswa. Ilungele ukunqunywa kwezakhiwo ezingavimbeli ilangabi zezindwangu ezilukiwe ezinganqamuki ilangabi, izindwangu ezilukiwe, nemikhiqizo eboshiwe.

Imininingwane Yomkhiqizo:

1. Izimo zokusebenza ze-DRK-07A ezivikelayo zokuhlola i-flame retardant kanye nezinkomba zobuchwepheshe eziyinhloko

1. Izinga lokushisa le-ambient: -10℃~30℃

2. Umswakama ohlobene: ≤85%

3. Supply voltage namandla: 220V±10% 50HZ, amandla angaphansi 100W

4. Isibonisi/ukulawula kwesikrini esithintwayo, amapharamitha ahlobene nesikrini sokuthinta:

a. Usayizi: amasentimitha angu-7, usayizi wokubonisa ophumelelayo ungu-15.5cm ubude no-8.6cm ububanzi;

b. Isixazululo: 800*480

c. Isixhumanisi esibonakalayo RS232, 3.3V CMOS noma i-TTL, imbobo ye-serial

d. Umthamo wesitoreji: 1G

e. Sebenzisa izingxenyekazi zekhompuyutha ezihlanzekile ze-FPGA ukuze ushayele isibonisi, isikhathi sokuqalisa esithi “zero”, futhi singasebenza ngemva kokukhanyisa

f. I-Adopt M3+ FPGA architecture, i-M3 inesibopho sokuhlaziya imiyalelo, i-FPGA igxile ekubonisweni kwe-TFT, isivinini nokuthembeka kuhola izixazululo ezifanayo.

g. Isilawuli esikhulu samukela amaphrosesa anamandla aphansi futhi singena ngokuzenzakalelayo kumodi yokonga amandla

5. Isikhathi somlilo wesicelo se-Bunsen burner singasethwa ngokungenasisekelo, ngokunemba kwe-±0.1s.

I-6 Bunsen burner ingatshekiswa ebangeni lika-0-45°

7. I-Bunsen burner high-voltage othomathikhi yokuthungela, isikhathi sokuthungela: isethwe ngokungafanele

8. Umthombo wegesi: Khetha igesi ngokwemibandela yokulawula ukuswakama (bona 7.3 ye-GB5455-2014), isimo A sikhetha i-propane yezimboni noma i-butane noma i-propane/butane igesi exubile; isimo B sikhetha i-methane enobumsulwa obungekho ngaphansi kwama-97%.

9. Isisindo esilinganiselwe sensimbi: 40kg

I-DRK-07A yokuvikela impahla yokuhlola i-flame retardant yokulawula ingxenye yesingeniso

1.Ta——isikhathi sokufaka ilangabi (ungachofoza ngokuqondile inombolo ukuze ufake isixhumi esibonakalayo sekhibhodi ukuze ulungise isikhathi)

2.T1——Rekhoda isikhathi sokuvutha kwelangabi esivivinyweni

3.T2——Rekhoda isikhathi sokusha okungenalangabi (okungukuthi, ukuthunqa) ekuhlolweni

4. Qala ucindezele isishisi se-Bunsen ukuze uye kusampula ukuze uqale ukuhlola

5. Misa-i-Bunsen burner izobuya ngemva kokucindezela

6. Igesi Cindezela igesi ukuze uvule

7. Ignition-cindezela kathathu ukuze uvutha ngokuzenzekelayo

8. Isikhathi-T1 ukurekhoda kuyama ngemva kokucindezela, futhi ukurekhoda kwe-T2 kuyama futhi ngemva kokucindezela

9. Londoloza-londoloza idatha yokuhlola yamanje

10. Ukulungiswa kwesikhundla-okusetshenziselwa ukulungisa isikhundla se-Bunsen burner kanye nesitayela

Isampula Lokulawula Nokuswakama

Isimo A:Isampula lifakwa ngaphansi kwezimo ezijwayelekile zomkhathi ezishiwo ku-GB6529 ukuze kulungiswe umswakamo, bese isampuli enomswakamo ifakwa esitsheni esivaliwe.

Umbandela B:Faka isampula kuhhavini ku-(105±3)°C imizuzu engu-(30±2), yikhiphe, bese uyibeka endaweni yokugcoba ukuze iphole. Isikhathi sokupholisa asikho ngaphansi kwemizuzu engama-30.

Futhi imiphumela yesimo A kanye nesimo B ayinakuqhathaniswa.

Ukulungiselela Isampula

Lungiselela amasampula ngokwemibandela yokulawula ukuswakama ebalulwe ezahlukweni ezingenhla:

Isimo A: Ubukhulu buyi-300mm * 89mm, izingcezu ezingu-5 ku-warp (longitudinal) isiqondiso kanye nezingcezu ezingu-5 ohlangothini lwe-weft (transverse), isamba samasampuli angu-10.

Isimo B: Usayizi ungu-300mm*89mm, izingcezu ezi-3 ku-warp (longitudinal) isiqondiso kanye nezingcezu ezi-2 ku-latitude (evundlile), ingqikithi

Indawo yesampula: Uma usika isampula, ibanga ukusuka emaphethelweni endwangu okungenani li-100mm. Izinhlangothi ezimbili zesampula zihambisana nesiqondiso se-warp (longitudinal) kanye ne-weft (transverse) yendwangu ngokulandelanayo. Ubuso besampula kufanele bungabi namabala nemibimbi. Amasampula e-warp awakwazi ukuthathwa emculweni ofanayo we-warp, futhi amasampula e-weft awakwazi ukuthathwa kuntambo efanayo ye-weft. Uma umkhiqizo uhlolwa, ama-seams noma imihlobiso ingafakwa kusampula.

Ukuqaliswa Kwamazinga

I-ASTMF6413: Indlela yokuhlola ejwayelekile yokuncipha komlilo kwezindwangu (ukuhlolwa okuqondile)

I-GB/T 13489-2008 “Ukunqunywa Kokusebenza Okushiswa Kwezindwangu Ezimbozwe Ngenjoloba”

I-ISO 1210-1996 "Ukunqunywa kwezimpawu ezivuthayo zamapulasitiki kumasampula aqondile axhumene nomthombo omncane wokubasa"

Izingubo zokuvikela ezinganqamuki amalangabi*Ezinye izingubo ezingashi

Izigaba zemikhiqizo

-

Ucingo

-

I-imeyili

-

Whatsapp

-

Phezulu